Two Platen Injection Moulding Machine

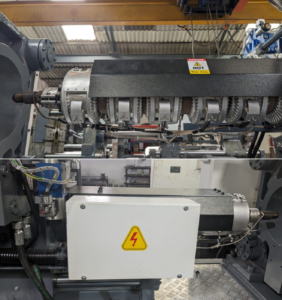

A two-platen injection moulding machine features two large platens that are used for clamping the mould. This design offers several advantages such as space efficiency, high precision, large mould capacity, and improved accessibility. The application of this machine is for medium or large-sized plastic parts moulding such as large auto parts, large household or logistic products, etc.

Our system uses four independent clamping cylinders in a modular design. This ensures an even force distribution, extending the life of the tie-bars and guaranteeing the best product quality. Thanks to our integrated design, maintenance is quick and efficient, leading to shorter downtimes.

Mold changes are made quick and convenient, as they can be changed from the side. Particularly advantageous for factories with height limitations, ensuring efficient mold changes without the need for overhead space.

Space Saving Two-Platen Solution

Space Saving Two-Platen Solution Short dry cycles

Short dry cycles Large mold space, compact machine design

Large mold space, compact machine design

Energy-efficient servo-technology

Energy-efficient servo-technology Fast response time and high positioning accuracy (± 0,05%)

Fast response time and high positioning accuracy (± 0,05%) High performance controls - Industry 4.0 capable

High performance controls - Industry 4.0 capable

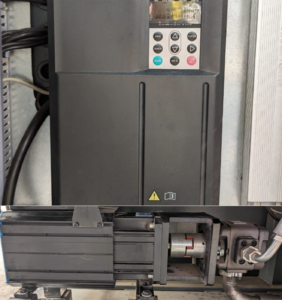

Servo Motor & Pump

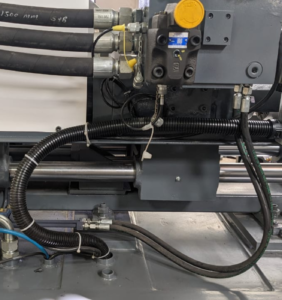

Servo Motor & Pump Ergonomic Hydraulic Layout for Easy Approach

Ergonomic Hydraulic Layout for Easy Approach Valves Placed near Actuators for Rapid Response

Valves Placed near Actuators for Rapid Response Continuous Oil Filtration with 10 Micron Filter

Continuous Oil Filtration with 10 Micron Filter Low Oil Level Audible Alarm & Motor Shut Down

Low Oil Level Audible Alarm & Motor Shut Down

Actual Current Display of Heating Zones

Actual Current Display of Heating Zones Heater Failure & Thermocouple Failure Detection

Heater Failure & Thermocouple Failure Detection Accurate PID Temperature Control Settable on Screen

Accurate PID Temperature Control Settable on Screen Auto Heat Startup & Shutdown

Auto Heat Startup & Shutdown Heat Standby after set number of Cycles

Heat Standby after set number of Cycles Soak Timer for Cold Start Protection

Soak Timer for Cold Start Protection High/Low-Temperature Alarm

High/Low-Temperature Alarm Set & Actual Temperature Data with Bar Graph

Set & Actual Temperature Data with Bar Graph

The new design incorporates additional functions and user benefits which greatly enhance the machine performance and part quality. With flexible clamping unit to injection unit combinations, the machine can be tailored to specific or general molding applications.

As a product with Technology to the Point, the new generation of the Two platen machine provides a wide variety of combination possibilities in a compact footprint, which maximizes the usable space of the plants to the customers’ benefit. No matter large parts such as trash bins and logistics boxes, or high-precision automotive parts and high-tech parts with high surface quality such as white goods, Dyota Series provides the best solution for customers.