Thin Wall Injection Molding Machine

_

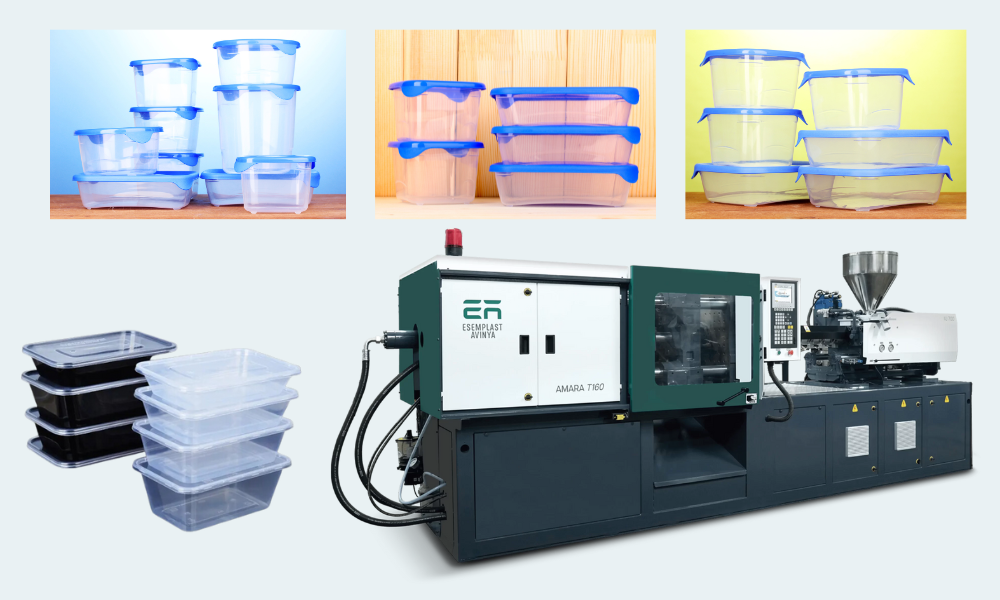

Plastic injection molding has revolutionized manufacturing processes across industries, allowing for the mass production of precise, lightweight, and durable plastic parts. A thin wall plastic injection molding machine is an advanced solution designed specifically for producing thin-walled components, which are highly sought after in sectors like packaging, medical devices, electronics, and consumer goods. These machines ensure high efficiency, speed, and accuracy, making them an essential asset for manufacturers aiming to meet the increasing demand for lightweight and strong plastic parts.

Thin Wall Injection Moulding Machine Manufacturer

_

Esemplast Avinya stands at the forefront of thin wall plastic injection molding machine technology, offering high-performance solutions to meet the demanding requirements of modern manufacturing. Our machines are designed with precision and efficiency in mind, ensuring that every product produced meets the highest standards of durability and accuracy. Whether you are producing food containers, medical devices, or other thin-walled products, our machines provide unmatched quality and reliability.

As leading thin wall injection molding machine suppliers, we understand the unique challenges associated with thin-wall molding, including maintaining structural integrity and minimizing material use without compromising on quality. Our injection molding machines are specially engineered to meet these challenges, ensuring that your production process is streamlined and cost-effective.

Key Features of Our Thin Wall Plastic Injection Molding Machines:

High-Speed Production

Our machines are built for speed, enabling manufacturers to produce thin-walled parts at higher rates without compromising precision or quality.

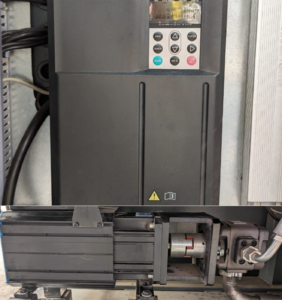

Energy-Efficient Operation

Equipped with energy-efficient components, our machines minimize power consumption, helping you lower operational costs and reduce your carbon footprint.

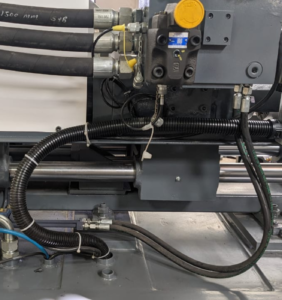

Precision Engineering

Our injection molding machines use cutting-edge technology to deliver precision in every part, ensuring consistent thickness, strength, and surface finish in every product.

Durability and Reliability

Built with robust components, our machines offer long-lasting performance, reducing downtime and increasing productivity for your operations.

Customizable Solutions

We offer a range of machine sizes and capabilities, allowing you to customize solutions to fit your specific production needs.

Machine

_

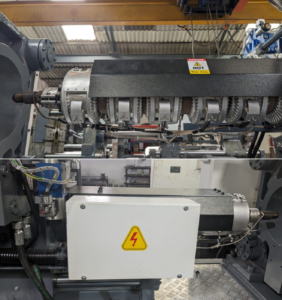

Amara Series

Toggle type injection moulding machine

_

Equipped with some of the industry-defining features, AMARA is the flagship machine that we build with our highly Qualified team of engineers. With this finest piece of machinery, it’s our constant pursuit to outperform the established benchmarks and achieve unprecedented performance for our clients.

Ekaiva Series

Injection blow moulding machine

_

The machine is a full automatic injection blow moulding equipment, suitable for processing PP, PS, PE, SAN, PMMA, PC, PETG, PEN and other thermoplastic, which widely used in pharmaceutical, health care products, food, beverage and cosmetics, etc.

Dyota Series

Two platen injection moulding machine

_

A two-platen injection moulding machine features two large platens that are used for clamping the mould. This design offers several advantages such as space improved accessibility. The application of this machine is for medium or large-sized plastic parts moulding.